In the ever-evolving landscape of construction, a revolution is taking place, reshaping the very foundations of how homes are envisioned and built—enter 3D printed housing. This transformative technology isn’t just a glimpse into the future; it’s a tangible force changing the dynamics of the construction industry.

In this in-depth exploration, unravel the origins, current applications, and the limitless potential of 3D printed housing, ushering in a new era of innovation.

Post Contents

Understanding 3D Printed Housing

Background and Origins

The roots of 3D printed housing trace back to the early 2000s when the convergence of additive manufacturing and construction led to a groundbreaking concept. 3D printing homes emerged as a cost-effective and sustainable alternative to traditional construction methods, sparking excitement and possibilities within the industry.

How 3D Printing Works in Construction

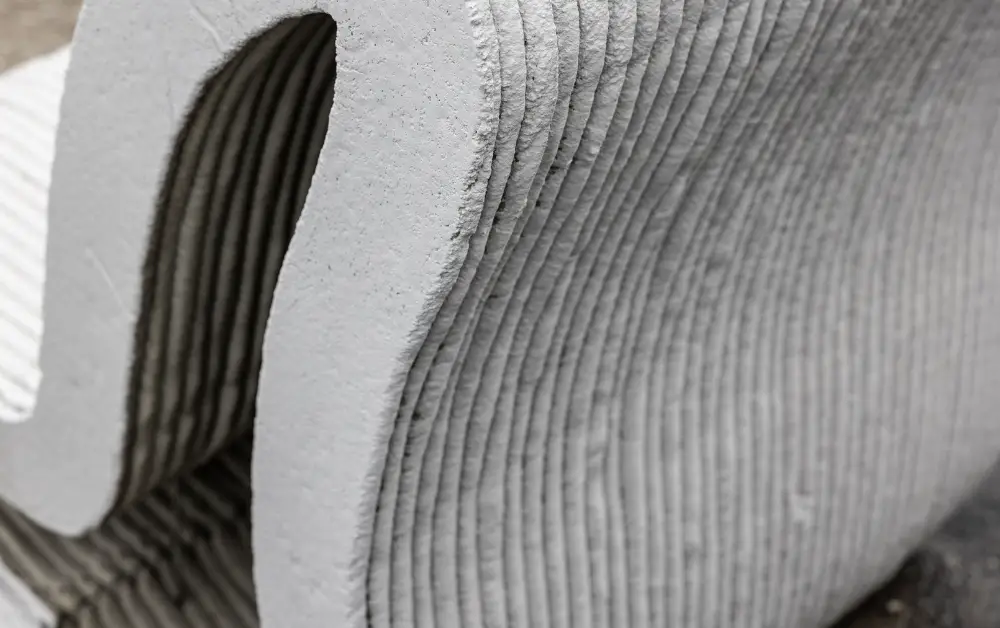

At its essence, 3D printing in construction involves the layer-by-layer deposition of materials, often cement-based, to construct entire structures. This automated process significantly reduces construction time and labour costs, offering a tantalizing glimpse into a future where efficiency and precision redefine the norms of the industry.

Famous Applications of 3D Printed Housing

Global Success Stories

Across the globe, architects and construction visionaries are embracing 3D printing to address housing challenges. Notable projects in the Netherlands, China, and the United States showcase the adaptability and versatility of this innovative construction method. These success stories underscore the potential of 3D printing to revolutionize the housing sector on a global scale.

The Netherlands – Project Milestone

In the Netherlands, a groundbreaking project called “Project Milestone” has demonstrated the transformative potential of 3D printing in housing. This collaborative effort between Eindhoven University of Technology and various construction partners aims to develop a community of 3D printed houses. The project focuses on creating customizable, sustainable, and energy-efficient homes.

The use of 3D printing technology allows for intricate designs and precise construction, emphasizing the adaptability of this method to diverse architectural preferences and environmental considerations.

China – Winsun’s Construction Ventures

China has been at the forefront of 3D printing applications in construction. Winsun, a Chinese construction company, has successfully printed entire buildings using a mixture of recycled construction waste and cement. Notably, Winsun’s projects include residential structures, villas, and apartment buildings.

The adaptability of their technology is evident in their ability to construct a variety of building types, addressing both urban and rural housing needs. Winsun’s initiatives underscore the potential of 3D printing to address housing challenges on a large scale and with sustainable materials.

United States – ICON and New Story in Texas

In the United States, ICON, in partnership with the nonprofit New Story, has completed a significant 3D printing project in Austin, Texas. The collaboration aimed to provide affordable housing solutions through the construction of a community of 3D-printed homes. The adaptability of ICON’s technology is highlighted in its ability to produce entire neighbourhoods efficiently.

The use of 3D printing in this project demonstrates its versatility in addressing housing affordability issues, showcasing the potential for widespread application in various socioeconomic contexts.

Economic and Environmental Benefits

The economic advantages of 3D printed housing are compelling. Reduced construction times lead to lower labour costs, and the ability to use local materials minimizes transportation expenses. Additionally, the sustainable nature of 3D printing aligns with the growing emphasis on eco-friendly construction practices, providing a holistic approach to building homes for the future.

Advantages of 3D Printed Housing

Speed and Efficiency

Among the most significant advantages of 3D printed housing is the speed of construction. Traditional methods that may take months or even years to complete a housing project can be replaced with 3D printing technology that erects a home in a few days. This rapid construction capability addresses the urgent need for efficient solutions in the face of global housing shortages.

Design Freedom and Customization

Beyond speed, 3D printing allows architects and homeowners unprecedented design freedom. The layering process enables intricate and customizable designs, challenging conventional notions of what a home should look like. This flexibility opens the door to more personalized and aesthetically pleasing living spaces, marking a departure from the uniformity of traditional construction.

Energy Efficiency

3D printing allows for the integration of energy-efficient features directly into the design. This can include optimized insulation, passive heating and cooling systems, and other sustainable practices, contributing to long-term energy savings.

Versatility in Materials

3D printing can utilize a variety of construction materials, including concrete, plastic, and even recycled materials. This versatility allows for experimentation with different materials to find the most suitable and sustainable options for construction.

Overcoming Challenges and Concerns

Material Innovation

While the concept of 3D printed housing is exciting, challenges persist, particularly related to materials. Ongoing research and development efforts are focused on finding durable, sustainable, and cost-effective materials that can withstand the test of time.

Regulatory and Perceptual Hurdles

As with any disruptive technology, navigating regulatory frameworks and overcoming public skepticism is expected. The construction industry must collaborate with governments and communities to establish standards and address concerns regarding the safety and longevity of 3D printed structures.

Future Prospects and Innovations

Scaling Up Production

Still, the potential for scalability in 3D printed housing is immense. As technology advances and becomes more widely adopted, the construction industry could witness an era where entire neighbourhoods are printed in a fraction of the time it takes using traditional methods. This scalability holds the promise of addressing housing shortages on a massive scale.

Integration of Smart Technologies

Looking ahead, the integration of smart technologies into 3D printed homes is a natural progression. From energy-efficient systems to Internet of Things (IoT)-enabled home automation, the synergy between 3D printing and cutting-edge technologies.

The Wrap Up

Embark on a journey into the forefront of construction. This captivating exploration takes you beyond traditional building methods, delving into the architectural revolution that is reshaping the very foundations of home construction. As cutting-edge technology intertwines seamlessly with sustainability, witness the birth of a new era where each layer of innovation contributes to a sustainable tomorrow.

Step into a realm where 3D printing transforms the blueprint of housing, offering unprecedented efficiency and precision. The symphony of architectural prowess and technological advancement orchestrates a narrative of homes emerging layer by layer, defying the conventional norms of construction.

Frequently Asked Questions

1. What is 3D-printed housing?

3D printed housing is a revolutionary construction method that utilizes 3D printing technology to create entire buildings layer by layer. This innovative approach offers advantages in speed, cost-efficiency, and design flexibility, transforming the traditional construction landscape.

2. How does 3D printing in construction work?

3D printing in construction involves using specialized 3D printers that deposit construction materials layer by layer to create a structure. Common materials include concrete or other cementitious mixtures. The process is precise, allowing for intricate designs and efficient construction.

3. How does 3D-printed housing contribute to sustainability?

3D-printed housing can contribute to sustainability by reducing material waste, using recycled materials, and incorporating energy-efficient designs. The efficient use of resources and the potential for eco-friendly materials make 3D-printed housing an environmentally conscious construction method.